Knowledge base

What is the difference between an EPAL pallet and a non-standardised pallet?

EPAL 1 is the most popular pallet in Europe with dimensions of 800×1200 mm. The deck boards (arranged lengthwise) and the three stringers arranged along the pallet are made of solid wood, while the blocks can be made of solid or particle wood. EPAL pallets are certified products and properly marked. Their production and repair are governed by special regulations. The purchase of a standardised pallet guarantees the quality, reusability, and longevity of the pallet.

What do the markings on an EPAL pallet block mean?

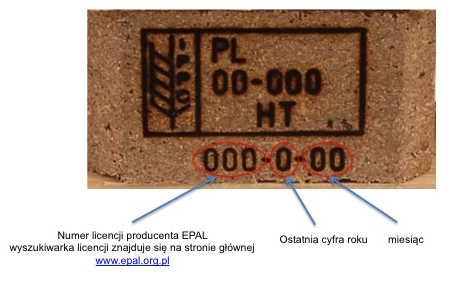

On the centre block, each EPAL Euro-pallet must have the manufacturer’s licence number and the year and month of manufacture.

Licence number – a three-digit designation.

Year of manufacture – a single-digit designation.

Month of manufacture – a two-digit designation.

Every new EPAL Euro-pallet manufactured under the guaranteed EPAL quality system must undergo ISPM15 phytosanitary treatment. Placing an appropriate mark on the central block confirms that phytosanitary treatment has been done.

What does the marking ‘HT’ on the pallet mean?

Heat treatment within the meaning of ISPM 15 (International Standards for Phytosanitary Measures No. 15) consists in heating the wood in such a way that a temperature of at least 56°C is reached in its core, i.e. in the areas that are the farthest from the surface. This temperature must be maintained for at least 30 minutes. If this is done, the wood is considered to have been thermally sterilised, i.e. the vast majority of known organisms are irreversibly inactivated. Wooden packaging, e.g. a pallet, subjected to such treatment may be marked with the letters HT, which stand for Heat Treatment.

What is the difference between ‘one in one’ and ‘one on one’ loading methods?

One in one:

Pallets are arranged in nested structures, which enable one to be placed onto (inserted into) another. They are interspersed in such a way that every other pallet is turned upside down and its blocks go between the blocks of the next one, thus allowing maximum use of the available loading and storage space. This method of stacking may prevent the automatic picking of pallets from a pile in production lines which are not standardised.

One on one:

The pallets are stacked one on top of another in column stacks. Each pallet stands on the top deck of another.

What are the benefits of loading pallets one on top of another?

Pallets arranged in the 1/1 (one on one) system are dedicated to customers who have automated production lines for loading pallets directly onto the production belt.

What is the moisture content of a standard pallet?

The moisture content of new Euro-pallets must not exceed 22%. On the other hand, special pallets produced at the customer’s request can have any moisture content levels.

What is the difference between blue stain fungi and mould?

Wood becomes mouldy because of fungal growth that results from inappropriate storage of wood. The appearance of mould is favoured by high humidity, limited air circulation, and moderately high temperatures. The quality of mould-infected wood deteriorates, so the pallet may fail to meet the required standards. Therefore, it is important that the pallet manufacturer has the appropriate infrastructure in place to minimise the risk of mould.

Very often, mould stains are confused with blue stain fungi, which, according to the Wood Technology Institute in Poznań, is only an aesthetic change of wood colour that does not impair the performance of the material. A pallet discoloured by blue stain fungi has not lost any of its value.

Does the appearance of blue stain fungi disqualify a pallet?

According to the Wood Technology Institute in Poznań, blue stain fungi do not impact the parameters of wood, or by extension, the finished products. Pallets with blue stain fungi can be safely used to carry goods.

Is it possible to design a pallet that is tailored to my needs?

Yes, it is. Our specialists will be pleased to present a design and to manufacture pallets that meet your individual requirements. We can also produce a pallet according to your drawings.

How soon can you deliver the pallets?

In case of EPAL, CP, and standard industrial pallets, orders are filled in Poland within 48 hours. For deliveries abroad, the lead time is 2–4 working days. For special pallets, the first delivery is made within 5–12 working days, subject to the availability of materials. PalettenWerk offers you the opportunity to arrange a buffer storage and on-call delivery. In such a case, the lead time for pallets is 48 hours in Poland and 2-4 working days abroad.

Can you mark pallets with non-standard signs (e.g., our logo)?

Yes, it is. It is possible to mark pallets according to a design sent by the customer. This may be a company logo or another symbol to distinguish the pallet.

How do you mark pallets?

In order to apply the symbols, we use the techniques of hot stamping and printing with the use of professional, high-resolution printers. Additionally, in our modern paint shops it is possible to mark pallets by painting their contour or the whole surface any colour.

Do you offer pallet tracking systems?

Yes, PalettenWerk – as one of the most technologically advanced pallet manufacturers – offers the option to print QR codes on pallets or to equip them with RFID tags. Both solutions can be adapted to your own tracking system.

What does the process of pallet quality control look like?

Our plant received ISO 9001:2015 certification after meeting strict quality requirements. These requirements are observed at every stage of production, which involves many processes and activities.

What certificates does your company hold?

PalettenWerk have all the necessary certificates and approvals for pallet production, for example:

- EPAL licence

- ISO 9001:2015 certification

- IPPC certificate

- PEFC certificate

Which regions do you deliver pallets to?

PalettenWerk, as one of the main manufacturers of pallets in Poland and Europe, export almost 70% of production, or almost 500,000 pallets per month. Our customers are based in 17 European countries. Apart from Poland, the largest foreign markets include Italy, Germany, Switzerland, France, and Austria. Our other sales markets are Czechia, Lithuania, Slovakia, Romania, Denmark, Hungary, Belgium, Slovenia, Serbia, the Netherlands, Spain, and the United Kingdom. We are not afraid of challenges, and we are constantly adding new customers with new destinations.

What does the pallet sales process look like?

The customer’s requirement is the main factor that initiates the whole process. PalettenWerk is the only correct answer if the word ‘pallet’ is part of that requirement.

From the very first contact, our consultants take an individual approach to determine the actual needs of a given customer. Just as everyone has to choose the right shoe size for themselves, choosing the right pallet guarantees comfort and obvious savings in business. After the customer communicates their requirements, the sales consultants – in cooperation with the designers and the logistics department – prepare an offer. It meets the customer’s expectations and provides the best price-to-quality ratio. The client actively participates in the whole process, influencing the final outcome. After an offer is accepted, samples are produced and delivered to the customer upon request. The last stage is the beginning of a business relationship.

Do you use certified components?

When using certificates such as PEFC, PalettenWerk is obliged to use the services of proven suppliers who offer only certified products. Everything is monitored by numerous standards which have been established and are enforced by global organisations. In addition, PalettenWerk itself organises audits at its suppliers to check the quality of the raw material supplied.

How can I place an order for pallets with you?

Please place your orders via email with our sales consultants or at palety@palettenwerk.pl.

What is the minimum order quantity?

The minimum order quantity depends on the design of the pallet, and it can be specified by contacting us at palety@palettenwerk.pl. However, please note that the minimum quantity will be expressed as a three-digit number.

What are the working hours of your company?

The individual departments of our company have different working hours. Customer service is provided from 8:00 a.m. to 4:00 p.m. and loading and acceptance of goods from 6 00 a.m. to 10:00 p.m., Monday through Friday.

How do you prepare your offer? What factors determine the price of pallets?

The price of a pallet depends on:

- the market price of timber

- the pallet design

- one-time volume

- the total quantity of pallets ordered in a year To receive an offer, please send your enquiry to one of our sales consultants or to palety@palettenwerk.pl.

Can you keep minimum stock levels for me?

Yes, we can maintain minimum stock levels. For more details, please contact our sales consultant.